Windshield damage rarely starts as a dramatic crack across the glass. Most often it begins as a tiny star or pit from a bit of gravel that bounced up at highway speed. Then temperature swings, a pothole hit, or a car wash brush nudges that chip into a spreading crack. I have watched drivers ignore a chip for a windshield chip repair Cherryville week, then two, then through a hot spell, only to show up when the glass can no longer be repaired. The difference between catching it early and waiting can be hundreds of dollars and an entire day without your car.

This is a practical guide to identifying what you can handle, what demands a quick professional repair, and how to avoid tipping a repairable chip into a full Windshield Replacement. Along the way, I will cover how Auto Glass construction affects damage, what Mobile Windshield Replacement can and can’t do, and when to plan for Windshield ADAS Calibration after service.

What a chip really is and why it spreads

Auto Glass on most vehicles uses laminated safety glass for the windshield and tempered glass for side and rear windows. Laminated windshields sandwich a polyvinyl butyral interlayer between two layers of glass. That thin plastic layer keeps the glass from shattering and helps block UV, but it also changes how damage propagates.

A rock chip is not just a dot. The visible mark is the surface crater, but small cracks often radiate beneath it in a cone shape. Every time the glass flexes, those hairline cracks flex too. Heat expands the outer glass layer more than the inner layer, the defroster warms one area while the edge stays cold, and the windshield continues to bear the constant subtle torsion of the body while driving. That chip becomes a stress concentrator. Given enough cycles of expansion and vibration, it becomes a crack.

The reason early repair works is simple. A quality repair injects resin into the air-filled voids, bonds the fractured glass to itself, and restores structural integrity. You do not make the damage invisible in all angles, but you stop the crack from growing and restore strength. Once the crack grows too long or reaches certain areas, the repair’s ability to hold it back drops quickly.

How to judge a chip at a glance

There is no need to carry calipers. A few rules of thumb will tell you if a chip is likely repairable:

- Size and type matter. Bullseyes and star breaks up to about a quarter in diameter, and combination breaks under a few inches, are often repairable. A single straight crack can usually be repaired if it is shorter than the length of a dollar bill, roughly six inches. Once a crack runs longer or splinters in multiple directions, replacement becomes the safer option.

Edges are tricky. If the damage sits within an inch or two of the windshield’s edge, the glass is under higher stress in that area. Edge cracks tend to spread even after repair. Many technicians decline edge-area repairs for that reason.

Impact points count. Two chips that intersect or a chip that has multiple impact points often means the laminate has taken a bigger hit and may not respond predictably to resin.

Driver’s line of sight is a special case. Even a properly repaired chip can leave a faint blemish. If damage sits right in front of your eyes at the wheel, some shops choose replacement for safety and clarity, depending on state regulations and your comfort.

If you are unsure, treat it as repairable and act quickly. Waiting turns “maybe fixable” into “definitely replace.”

The first hour after a chip

What you do right after the impact can save the glass. The goal is to keep moisture and dirt out of the fracture, and to avoid flexing the glass unnecessarily before a technician can inject resin. Do not jab at it with a fingernail or try to pry out loose glass. That pushes debris deeper.

If you keep a chip saver sticker, place it over the damaged area on a dry surface. A small piece of clear tape can work in a pinch for a day. Avoid car washes and don’t blast the defroster on high heat across the chip. If the weather is near freezing, try not to park with one side of the windshield in bright sun and the other in shade. Temperature gradients push cracks.

I have taken vehicles where the chip looked worse than it was because wind-driven rain forced fine grit into the cavity. We still repaired them, but the clarity after curing was not as good as a clean, dry, same-day chip.

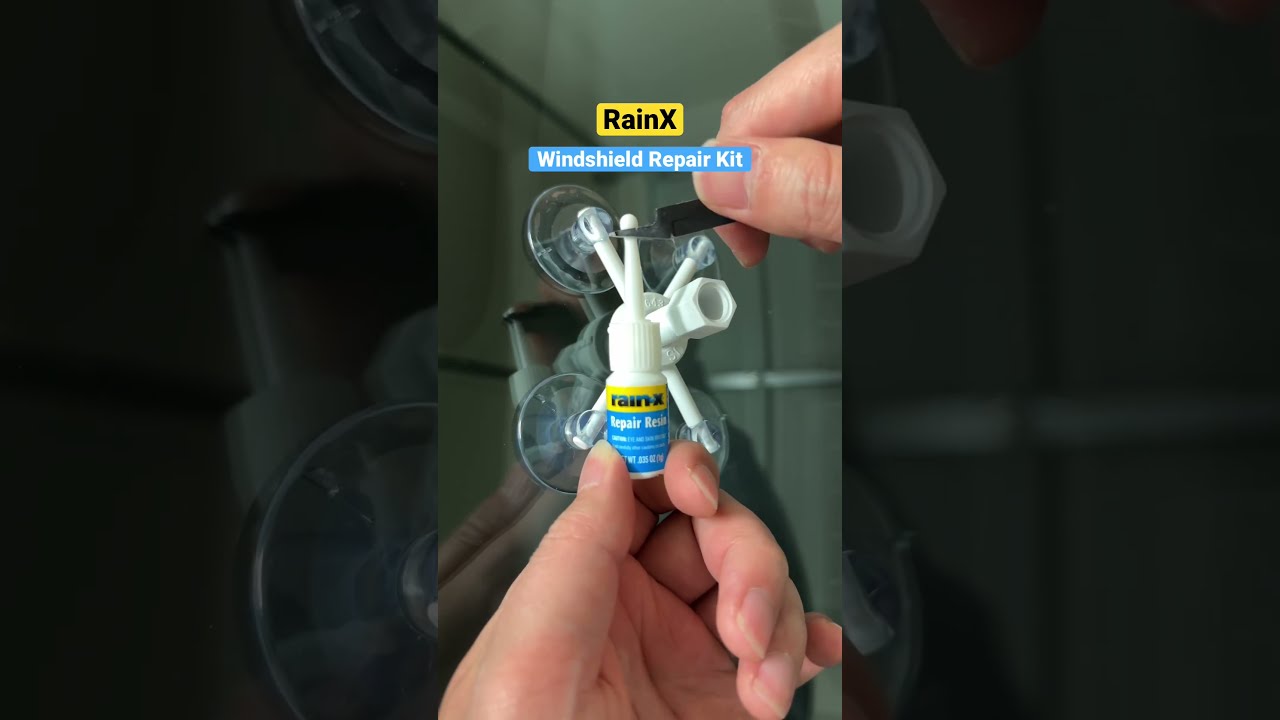

DIY tools versus professional repair

You can find windshield repair kits at most parts stores. They can help in a pinch, and I have seen better-than-expected results on simple bullseyes that were clean, fresh, and dead center in the glass. If you go that route, read the instructions, use them on a warm day, and be patient about pressure and curing time. The less rushed the process, the less chance you trap bubbles and the more resin you pull into the microcracks.

Where DIY falls short is consistency. Professional injectors and bridges can create and hold a stronger vacuum, then apply controlled pressure to push resin deep into star legs. A trained technician also knows when to flex the glass gently to open microfractures and when to stop to avoid turning a star break into a crack. We can also polish the pit with a curing tab and UV lamp to a better optical finish.

If you rely on driver-assistance features tied to the windshield, or if the chip has any legs starting, I recommend a professional repair. The small savings of DIY can disappear quickly if the repair fails and you need a Windshield Replacement.

Why time and temperature decide your fate

Most chips fail to stay small because of two things: repeated temperature swings and body flex. Morning frost and afternoon sun drive expansion and contraction cycles. That little star becomes a crack that crawls an inch each day until suddenly it races across the glass. The speed bump that did not feel that bad to the suspension hits the windshield too. The glass carries a part of the car’s torsion, and every bounce nudges the weak point.

If you cannot get to a shop right away, park in shade, avoid slamming the doors, and go easy over speed bumps. Even closing the door with the windows up can pressurize the cabin enough to flex the glass slightly. On older vehicles with stiffer seals and no pressure relief vents, that small jolt can push a stressed chip into a run.

The repair process, in plain terms

A standard professional chip repair takes around 30 minutes for a straightforward bullseye, a bit longer for combination breaks or multiple chips. The steps look simple, but the quality lives in the details.

First the technician inspects from both sides and cleans loose glass. If moisture is in the chip, we often use gentle heat to evaporate it. Then a bridge with a suction base centers an injector over the pit. A vacuum cycle pulls air and any fine debris out, then a pressure cycle pushes resin in. Cycling back and forth helps fill the legs of a star or the shallow delamination around the impact. Many resins use UV light to cure, so a lamp or sunlight hardens the repair. Finally, we fill the surface pit, lay a curing film, level it with a razor once hardened, and polish.

After curing, you should expect the damage to look significantly better, sometimes nearly disappear from certain angles. From other angles you may still see a faint mark. The main goal is strength and crack prevention, with aesthetic improvement as a bonus.

Insurance and cost realities

Rock chip repairs often cost less than an oil change. Depending on your area, expect 60 to 150 dollars for the first chip and a smaller add-on for additional chips repaired at the same visit. Many insurance policies waive the deductible for windshield repairs because it saves the carrier money compared to a replacement. If you carry comprehensive, call your insurer or check your app. You can often schedule the repair directly, and it will not typically count as a claim that raises your premiums.

Windshield Replacement costs are substantially higher. A basic windshield on an older sedan might be a few hundred dollars installed. A modern windshield with acoustic interlayers, rain sensors, heated wiper parks, and driver-assist cameras can run four figures. That does not include the time and cost of Windshield ADAS Calibration when required. Every chip you repair promptly is an avoided replacement.

When repair is no longer the smart move

There are limits. I do not repair:

- Cracks longer than a dollar bill, or any crack that continues to spread while I watch it. Damage that penetrates completely through the laminate. Chips directly in the driver’s critical line of sight when the end result will hinder clarity. Multiple impact points clustered together that suggest deeper laminate damage.

At that point, Auto Glass Replacement is your path. Do not put tape over a long crack and hope for a miracle. Replacement done correctly restores your car’s safety, visibility, and structural performance in a crash. The windshield is part of the roof support system and a big player in airbag deployment. A weak bond or cracked sheet compromises both.

What to expect during Windshield Replacement

A good replacement is more than swapping glass. The technician will protect the interior, remove trim and cowl pieces, cut the old urethane safely without scratching the pinch weld, and prep the frame. Any rust must be addressed, not ignored. Primer and fresh urethane get applied with the right bead size and shape, and the new windshield is set with proper alignment. The car then needs a safe drive-away time, which can range from 30 minutes to several hours depending on the urethane used, temperature, and humidity.

Mobile Windshield Replacement is a lifesaver when your schedule is packed. If weather cooperates and a stable, level surface is available, mobile service delivers the same quality as in-shop. I avoid mobile installs in freezing rain, high winds, or on uneven gravel. Resin and urethanes are sensitive to temperature and contamination. A shop environment reduces variables. Still, for many daily jobs, mobile works well and saves you the trip.

ADAS: calibration is not optional

Modern vehicles often place cameras and sensors at the top of the windshield. Lane keeping, adaptive cruise, traffic sign recognition, and collision warning rely on those sensors seeing the world through the exact right angle and distance. Replace the glass and you change that relationship slightly. That is where Windshield ADAS Calibration comes in.

Some vehicles allow static calibration in a shop with targets and precise measurements. Others require dynamic calibration on a specific road type at certain speeds. Many need both. Skipping this step invites false warnings or, worse, a system that does not intervene when it should. Expect calibration to add time and cost. Look for a shop that can perform or coordinate it the same day, and ask for documentation that the system passed. If your car has aftermarket tint or a windshield with coatings, make sure the glass installed is compatible with your sensors.

A common worry is that a repair near the camera may require calibration. Generally, chip repairs do not change sensor geometry, but if the damage or repair sits in the immediate field of view of a camera, some manufacturers recommend calibration. When in doubt, check your owner’s manual or consult a specialist.

Seasonal traps that turn chips into cracks

I see predictable patterns each season. Early spring brings freeze-thaw cycles that punish unrepaired chips. Drivers run the defroster high in the morning, then park facing the sun at lunch. By the afternoon commute the chip has grown legs.

Summer heat bakes the windshield. Parked cars bake even more, and the temperature difference between the center of the glass and the shaded edges can be stark. A sudden splash from a car wash or an afternoon thunderstorm cools the surface quickly. That thermal shock can trigger a run.

Autumn and winter bring road gravel and salt. Chips multiply from highway miles, and wiper blades drag grit over the glass. If you can see small pits across your field of view when the sun is low, your glass has taken a beating. Replace the blades, clean the windshield carefully, and fix any new chips before the first hard freeze.

Myths that cost people money

A few misconceptions show up often:

It’s just a tiny chip, it can wait. Chips do not respect calendars. I have watched a chip sit quiet for a month, then crack across the glass in a single afternoon. You want to control the timing, not gamble on it.

Repair makes the glass weak. Done correctly, repair strengthens the damaged area by bonding it. No repair restores the glass to brand new condition, but the repaired spot is notably more stable than leaving a void.

If I can’t see it from inside, it’s fine. Many chips are more visible from the outside. The interior view can hide fine legs that are already spreading. Inspect both sides in good light.

All glass is the same. It is not. Quality differences exist in glass clarity, acoustic damping, sensor compatibility, and fit. For vehicles with advanced sensors, using the correct windshield is critical.

Insurance will raise my rates if I claim a repair. Policies vary, but many insurers specifically encourage repairs without deductible. A call to confirm beats assumptions.

A simple maintenance philosophy

Windshield care feels reactive, but you can build a light routine that reduces risk and catches issues early. Keep washer fluid topped with a formula that cuts bug residue. Replace wiper blades twice a year or when they streak. Clean the glass properly with a dedicated glass cleaner and a fresh microfiber, not a worn shop rag that drags grit. During long trips on gravel-sprayed roads, give yourself extra following distance behind trucks and freshly resurfaced sections. If you hear that sharp tick on the glass, pull over when safe, inspect, and cover the spot if needed.

The best thing you can do is treat a chip as a time-sensitive repair, not cosmetic fluff. Make a call the same day if possible. Most shops can fit a rock chip repair between larger jobs or send a mobile tech to your home or office. The appointment will take less time than a lunch break.

How to choose a shop that will get it right

Reputation matters, but so does the conversation. Ask about:

- Their approach to repair versus replacement. A good shop repairs when safe and replaces when necessary, not the other way around. The resins and equipment they use. Name-brand materials and UV curing lamps signal care and consistency. Warranty on repairs. Most offer a warranty that if a repaired chip spreads, they will credit the repair cost toward replacement. ADAS calibration capability. If your vehicle needs it, you do not want to drive around with uncalibrated systems. Mobile options and weather policies. A frank answer about when mobile is appropriate shows professionalism.

If the person on the phone rushes you or pushes for replacement without asking about the chip’s size and location, try another shop. Good Auto Glass providers know that today’s small repair often earns tomorrow’s replacement business when it is truly needed.

When replacement happens anyway

Even with the best care, some chips cannot be saved. Maybe you did not notice it until it grew overnight. Maybe it landed at the very edge where stress is highest. When Windshield Replacement is on the table, do a few things to make it smooth.

Confirm the exact glass part number for your trim. Vehicles often have multiple windshield variants: acoustic interlayer, solar coating, heated elements, camera brackets, and specific mounting pads. The wrong glass can be a headache to return and delay the job.

Plan for downtime. With Mobile Windshield Replacement, you can usually keep your day moving at home or work, but you still need to respect safe drive-away times. Avoid slamming doors or hitting rough roads until the urethane has cured sufficiently.

Schedule calibration. If your car uses forward-facing cameras or radar behind the glass, arrange Windshield ADAS Calibration with the install. Ask how long the process should take and what the shop needs for dynamic calibration routes.

Inspect the work. Look at the trim fit, the cowl alignment, and the interior dash for stray urethane. Water test if possible. A clean, quiet cabin without wind noise is the goal. If something feels off, say so right away. A good shop would rather adjust it now than hear about a whistle a week later.

A quick field story: the chip that almost got away

A customer called about a pea-sized bullseye on a mid-size SUV. It was high on the passenger side, fresh from a weekend road trip. They almost put it off for a month, but the forecast called for a heat wave. We repaired it that afternoon at their office parking lot. The resin filled completely, leaving only a faint mark.

Two weeks later, the same customer came back, this time with a friend who had ignored a similar chip. That chip had turned into a crack that ran from the center to the lower edge after a hot-cold wash cycle. The friend needed a new windshield, and because the vehicle had a camera-based lane assist system, it also needed calibration. The repair was a one-hour visit. The replacement and calibration took half a day and more than ten times the cost out of pocket due to a high deductible. Same road, same type of chip, different timing.

The bottom line

A windshield chip is a small problem with a short fuse. If you act while it is still just a chip, you keep the repair simple, cheap, and quick. You also avoid the cascade of costs and logistics that come with a full Windshield Replacement and any required Windshield ADAS Calibration. Respect the physics, buy yourself time with basic care, and partner with a shop that treats repair as a craft, not a sales funnel.

Auto Glass is one of those things you do not think about until it demands attention. With a bit of awareness and prompt action, you can keep it that way.